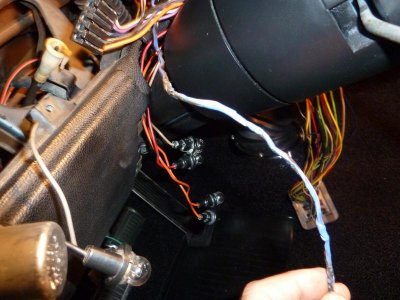

OK, too far for me to stop in; I'm up in the Blue Ridge Mtns. IMO no need to check the temp; this is abnormal, and it will progressively get worse. The heat is due to increased contact resistance, and causes a voltage drop to all sorts of systems in the car, like the ignition system. It also lowers the voltage to the voltage regulator (fed by the same circuit as the igntion) and that usually makes the alternator raise its charge voltage.

If you are not aware of it, then bulkhead connectors are another good source of problems; the whole battery charging current from the alternator, and all the interior circuits, lights, etc., goes back and forth through a couple of contacts (the 2 larger wires going in/out of the bulkhead connectors). This is another classic spot for corrosion, overheating, and melting.