Part 2 Cleaning and Inspection

About this Mopar:

Ok, finished with the machine work for valve height clearance and positive stop valve seals. Now for some deburring and casting "flash" removal. Also chasing any threaded holes with a tap.

I removed flashing in the pushrod areas and just around the ports, with the die grinder. Cleaned gasket surfaces and followed up with emery.

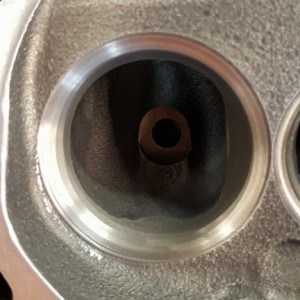

I didn't like the burr at the valve Seats. Just touched it with a 2" sanding disk.

I didn't like the burr at the valve Seats. Just touched it with a 2" sanding disk.

Bought a new parts washer. I cut a rack from an old fridge to set the heads on. You want to have all metal removal and sanding done before the final cleaning.

Bought a new parts washer. I cut a rack from an old fridge to set the heads on. You want to have all metal removal and sanding done before the final cleaning.

Useing my valve spring height mic, I'm measuring and picking out what size shim I'll be useing under each valve to get the total height the same on all of them. I bought an assortment of different shims. Notice I kept track of my measurements writing them on the head.

Have your parts laid out, some lube and a thin piece of plastic. Or you can buy the seal starter.

Useing the thin plastic to start the seal over the valve stem without any damage to it. Use lube!

I cut myself a short piece of 1/2" plastic pipe to tap the seal in place.

Checking the seal to retainer measurement. Looks good for my lift cam.

Checking compressed measurements and coil bind in a vise.

I made myself a "little friend" to hold my handle.

Use a little grease on the keepers so they stick to the stem.

I removed flashing in the pushrod areas and just around the ports, with the die grinder. Cleaned gasket surfaces and followed up with emery.

Useing my valve spring height mic, I'm measuring and picking out what size shim I'll be useing under each valve to get the total height the same on all of them. I bought an assortment of different shims. Notice I kept track of my measurements writing them on the head.

Have your parts laid out, some lube and a thin piece of plastic. Or you can buy the seal starter.

Useing the thin plastic to start the seal over the valve stem without any damage to it. Use lube!

I cut myself a short piece of 1/2" plastic pipe to tap the seal in place.

Checking the seal to retainer measurement. Looks good for my lift cam.

Checking compressed measurements and coil bind in a vise.

I made myself a "little friend" to hold my handle.

Use a little grease on the keepers so they stick to the stem.