hendo0601

Well-Known Member

I figured I would do a little write-up on how to check your steering and suspension parts. Let's face it, our cars aren't getting any younger and your steering/suspension components really take a beating out on the road and they will eventually wear out. If not caught early enough it can lead to all sorts of expensive problems down the road. Worn/damaged steering and suspension components can cause the vehicle to pull to one side or the other, ride rough, cause premature and uneven tire wear. Checking your steering and suspension components is easy to do and can be done in just a few minutes.

First things first you will want to do a simple visual check. Look at the shocks. Do you see oil leaking out past the piston down the body of the shock? Are the bushings intact or dry rotted/blown out? Look at the ball joint and tie rod end grease boots. Are the boots intact and full of grease or are they ripped to shreds with no grease visible? Torn/damaged grease boots can lead to premature part failure. Check the upper control arm bushings. Do they appear to be intact or can you see cracked rubber bulging out? These bushings are often overlooked and seldom replaced.

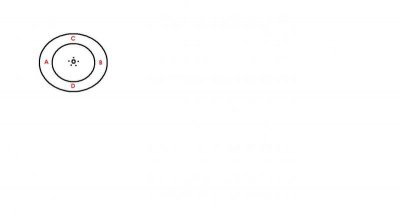

Next you will need to jack the front end up. It is critical to ensure you lift or support the vehicle under the lower control arms. To accurately check the ball joints the suspension has to be compressed and cannot be "hanging" as if jacked up under the frame. Refer to the illustration below for reference in the following steps.

To check the steering (inner and outer tie rods, pitman arm, idler arm) you will need to grasp the tire at points A and B and "shake" it back and forth. You should be moving the tire in quick movements. If any parts are worn you will be able to feel it. There should be no noticeable "slop" or movement in any of the steering components. It helps to have a helper with a flashlight looking at the steering components as you shake the tire to pinpoint any movement. Make sure you shake both tires. If you just shake the driver's side tire you may not notice a worn part on the passenger's side! Next grasp the tire at points C and D and attempt to shake the tire in and out. Any movement here could be either a worn ball joint or a loose wheel bearing. Again have a helper look at the ball joints with a flashlight and if no movement is seen, the movement is in the wheel bearings and they need to be repacked/adjusted. If there is play in the ball joint it will be seen as the spindle assembly moves and the control arms do not. This is known as "radial" movement. For the next step you will need a pry bar (or something similar, a tire iron works in a pinch). Place the pry bar under the tire at point D and attempt to pry the tire upwards. Any movement here will be seen as well as felt. Have your helper look at the ball joints again to pinpoint any movement. This is known as "axial" movement.

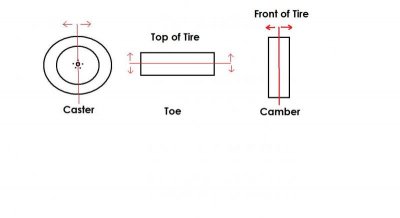

Worn/loose steering and suspension components will cause your front end to not be properly aligned, and proper alignment is crucial! Alignment consists of three different angles: Toe in/out, camber, and caster. Refer to the second illustration for a visual aid. Toe is the distance from the leading edge of the tire to the center line of the vehicle. "Toe in" refers to when the leading edges of the tires are pointed inwards, "toe out" the leading edges are pointing outwards. Excessive toe in/out can cause premature tire wear, steering instability, and your steering wheel will not be centered when driving. Camber refers to the tilt of the tire in/out relative to the center line of the vehicle (as viewed from above). Negative camber means the top of the tire leans inward, positive camber means it leans out. Some negative camber is desired as the tire will camber out when cornering and it creates a better contact patch with the road. Excessive camber (positive or negative) can cause premature uneven tire wear and pulling to one side or another. Caster is the tilt of the steering axis fore or aft (as viewed from the side). Caster is a non-wearing alignment angle, meaning it wont cause uneven/premature tire wear. Excessive caster can cause the vehicle to want to wander or drift, and will affect the "returnability" of the steering wheel when turning corners. Without the correct equipment and tools setting your alignment angles is all but impossible and not recommended. I included this section merely for reference and to help your understanding of your front suspension.

First things first you will want to do a simple visual check. Look at the shocks. Do you see oil leaking out past the piston down the body of the shock? Are the bushings intact or dry rotted/blown out? Look at the ball joint and tie rod end grease boots. Are the boots intact and full of grease or are they ripped to shreds with no grease visible? Torn/damaged grease boots can lead to premature part failure. Check the upper control arm bushings. Do they appear to be intact or can you see cracked rubber bulging out? These bushings are often overlooked and seldom replaced.

Next you will need to jack the front end up. It is critical to ensure you lift or support the vehicle under the lower control arms. To accurately check the ball joints the suspension has to be compressed and cannot be "hanging" as if jacked up under the frame. Refer to the illustration below for reference in the following steps.

To check the steering (inner and outer tie rods, pitman arm, idler arm) you will need to grasp the tire at points A and B and "shake" it back and forth. You should be moving the tire in quick movements. If any parts are worn you will be able to feel it. There should be no noticeable "slop" or movement in any of the steering components. It helps to have a helper with a flashlight looking at the steering components as you shake the tire to pinpoint any movement. Make sure you shake both tires. If you just shake the driver's side tire you may not notice a worn part on the passenger's side! Next grasp the tire at points C and D and attempt to shake the tire in and out. Any movement here could be either a worn ball joint or a loose wheel bearing. Again have a helper look at the ball joints with a flashlight and if no movement is seen, the movement is in the wheel bearings and they need to be repacked/adjusted. If there is play in the ball joint it will be seen as the spindle assembly moves and the control arms do not. This is known as "radial" movement. For the next step you will need a pry bar (or something similar, a tire iron works in a pinch). Place the pry bar under the tire at point D and attempt to pry the tire upwards. Any movement here will be seen as well as felt. Have your helper look at the ball joints again to pinpoint any movement. This is known as "axial" movement.

Worn/loose steering and suspension components will cause your front end to not be properly aligned, and proper alignment is crucial! Alignment consists of three different angles: Toe in/out, camber, and caster. Refer to the second illustration for a visual aid. Toe is the distance from the leading edge of the tire to the center line of the vehicle. "Toe in" refers to when the leading edges of the tires are pointed inwards, "toe out" the leading edges are pointing outwards. Excessive toe in/out can cause premature tire wear, steering instability, and your steering wheel will not be centered when driving. Camber refers to the tilt of the tire in/out relative to the center line of the vehicle (as viewed from above). Negative camber means the top of the tire leans inward, positive camber means it leans out. Some negative camber is desired as the tire will camber out when cornering and it creates a better contact patch with the road. Excessive camber (positive or negative) can cause premature uneven tire wear and pulling to one side or another. Caster is the tilt of the steering axis fore or aft (as viewed from the side). Caster is a non-wearing alignment angle, meaning it wont cause uneven/premature tire wear. Excessive caster can cause the vehicle to want to wander or drift, and will affect the "returnability" of the steering wheel when turning corners. Without the correct equipment and tools setting your alignment angles is all but impossible and not recommended. I included this section merely for reference and to help your understanding of your front suspension.