Gary_gtx67

Well-Known Member

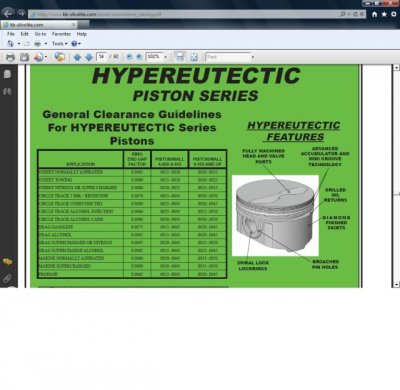

Ok everyone I finally broke down and after finding out my motor was pulling very weak compression and speratic numbers I pulled the motor. Only to find severly glazed cylinder walls and rings gaps at .031. My bore is a 4.275 and and I have the .030 over keith black hyper tech pistons. I am being told that the math to find the correct gap is .004 x bore = gap. Is this true? I also found this http://www.kb-silvolite.com/article.php?action=read&A_id=32

which led to this.http://www.kb-silvolite.com/calc.php?action=ring

It is just a street application.:eusa_eh:

which led to this.http://www.kb-silvolite.com/calc.php?action=ring

It is just a street application.:eusa_eh: