You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

intake gasket 383 mopar

- Thread starter brianhouchins

- Start date

Meep-Meep

дворянин

Nope. And in my opinion there is no need to. It's also likely you won't be able to even get the intake bolts started if you use gaskets that are thicker then the valley pan. A little sealer in the corners and rail and some around the ports and you're good to go. Keep it simple!

Funship32

Well-Known Member

Can't say I've ever seen that done although I have seen others use intake gaskets (1 set on each bank) along with a complete valley pan.

eric383

Well-Known Member

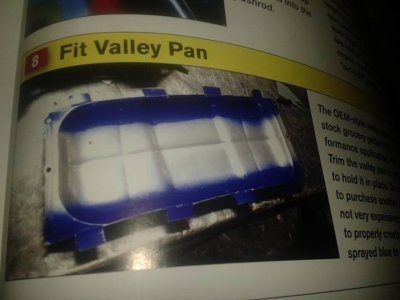

Did anyone else see last weeks Horsepower TV where they did a Mopar 400 stroker build? I thought it was kinda strange they used 2 intake gaskets on each side to sandwich the valley pan. I always thought this was too thick.

mr. b

Well-Known Member

I use valley pan and intake gasket on mine with aluminum intakes it will suck oil on intake ports if you do not use the gaskets.Bob

A383Wing

Well-Known Member

been running aluminum intakes for decades...still running just the stamped steel valley pan gasket. No extra paper gaskets here, never an oil sucking problem or anything like that...

If heads have been milled, you are supposed to take a percentage off each side of the intake as well so the mating geometry stays the same in order for the valley pan to seal all the way around the intake. People that have to use paper and makeshift gaskets under the intake to seal to the cylinder head have something wrong with angles of mating surfaces and the paper gaskets are just a "band aid" or "cover up" fix.

Bryan

If heads have been milled, you are supposed to take a percentage off each side of the intake as well so the mating geometry stays the same in order for the valley pan to seal all the way around the intake. People that have to use paper and makeshift gaskets under the intake to seal to the cylinder head have something wrong with angles of mating surfaces and the paper gaskets are just a "band aid" or "cover up" fix.

Bryan

- Local time

- 8:14 PM

- Joined

- Dec 4, 2009

- Messages

- 36,314

- Reaction score

- 48,222

- Location

- Pasadena, Texas

Actually, you should take the material off the head's port face and not the intake when you surface mill a set of heads, that way the intake will still fit other engines but if you mill the block, then it's up to you as to what you want to do. And I've also never done that to a valley pan but have heard of it before but the best bet is to do a mock up before you machine/mill an intake or the head to see how things fit. I've had aftermarket intakes that actually fit better once the heads or block were milled. Many times, the book way has not panned out and a mock up should always be done....

Funship32

Well-Known Member

Did anyone else see last weeks Horsepower TV where they did a Mopar 400 stroker build? I thought it was kinda strange they used 2 intake gaskets on each side to sandwich the valley pan. I always thought this was too thick.

Yeah I caught that episode too. As I said in a previous post: I've seen people do that before. My understanding is that they aid in sealing alum intakes due to different expansion rates but I've seen others run w/o them too (like me).