NZ 70 RR

Well-Known Member

- Local time

- 11:03 PM

- Joined

- Jul 11, 2013

- Messages

- 293

- Reaction score

- 155

- Location

- Nelson, New Zealand

Hi guys,

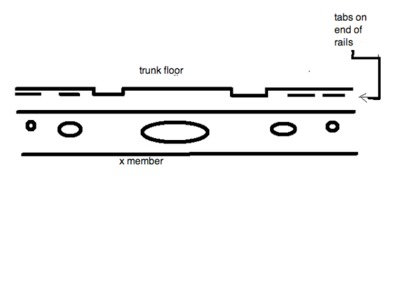

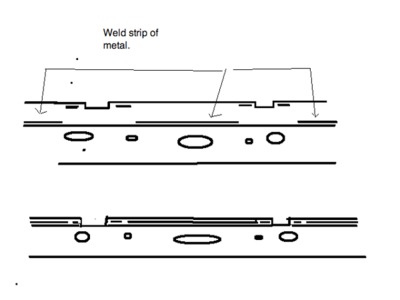

Hope the drawing below helps explain my question. When I fit my X member up to the trunk floor it makes contact with the tabs on the end of the frame rails and the indentations of the new trunk floor. Are these the only contact points that I can weld the x member too ? Should the x member and floor be touching all the way along ? Am I having this issue because I am putting the x member in in the wrong order.

help please

Tony

Hope the drawing below helps explain my question. When I fit my X member up to the trunk floor it makes contact with the tabs on the end of the frame rails and the indentations of the new trunk floor. Are these the only contact points that I can weld the x member too ? Should the x member and floor be touching all the way along ? Am I having this issue because I am putting the x member in in the wrong order.

help please

Tony