HYRDGOON

Well-Known Member

- Local time

- 10:24 PM

- Joined

- Apr 20, 2013

- Messages

- 3,375

- Reaction score

- 2,747

- Location

- Breslau, Ontario, Canada

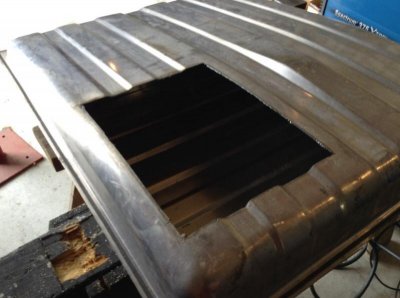

Ordered the Rims, tires and Headers yesterday also started the age-old battle of; how am I going to keep this thing cool?!. I talked to Bob at GlenRay yesterday and he was hesitant to commit that one of his best 22" radiators will get the job done on ~850HP. I appreciate his honesty. He said if I had the opening for the 26" Next Generation it would be no problem. He did say that I would need about 3500 CFM to get the job done and suggested I give Wizard a call. I have a call into them. he also told me that in a heads up comparison, with ALL things being equal, there is only about a 1% difference in cooling between Aluminum and Copper/brass radiators. The obvious advantage is weight with Aluminum.

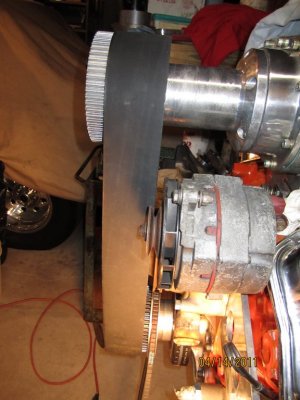

So here's where I'm at; I hate like hell to modify the radiator support in any way. I'm going to see what Wizard has to offer. I'm going to wait until I get the engine and driveline installed in order to see what kind of space I have to work with. From the water pump pulley flange it will be what I have now, what I don't know is the forward space that will be eaten up by the blower drive pulley/belt/idler...

As always, input/suggestions/comments greatly appreciated.

Wizard is Top Shelf and easy to deal with. If you give them the specs they'll build something that will get the job done.