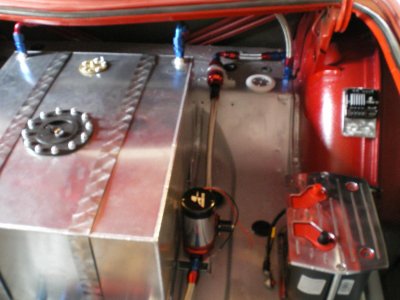

Looking for some input. Seems my Holley HP 150 bit the dust yesterday and I need a new fuel pump. Current set up is the HP-150 going to a Holley regulator with a split feed to each front and back bowels on a Holley HP 950 carb. The car is driven mostly on the street these days to and from crusies and shows. No fuel line return to the cell.

Easiest thing to do would be to order another HP150 since it would bolt right in place and one wire connect and I'd be back riding - but, I'm wondering if there is a better route to go? The 150 gph Holley seemed the right size for WOT runs (motor makes around 675-700 hp) so I don't think I need anything bigger, unless I go with a return / bypass. Anyone have thoughts on a quieter pump, more reliable, etc.? :icon_eyes:

Easiest thing to do would be to order another HP150 since it would bolt right in place and one wire connect and I'd be back riding - but, I'm wondering if there is a better route to go? The 150 gph Holley seemed the right size for WOT runs (motor makes around 675-700 hp) so I don't think I need anything bigger, unless I go with a return / bypass. Anyone have thoughts on a quieter pump, more reliable, etc.? :icon_eyes: