Propwash

Well-Known Member

- Local time

- 10:29 AM

- Joined

- Oct 29, 2009

- Messages

- 9,710

- Reaction score

- 4,323

- Location

- Island of Misfit Toys

Alright Fella's......I appreciate all the advice and idea's given on the build layout for my 512, got that pretty much nailed down. Thanks again! So, on to the next adventure, the Fuel System.

I spent a half an hour on the horn with George at Clay Smith Cams yesterday...Heck of a guy with quite a racing pedigree. Really enjoyed the stories about his aluminum '64 mopar back in the day, pretty much a priceless car now days. Anywho, I came to the decision to run their high volume mechanical fuel pump on the 512 (14-19 PSI @140GPH), being it's way more than adequate for my motor and I really don't want to play with the electric's.

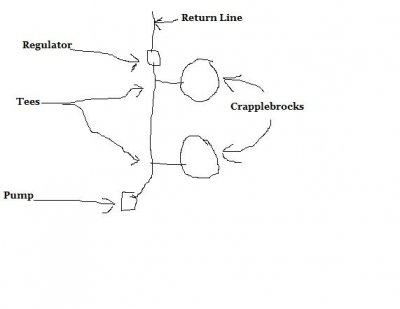

So...Here's what George recommended for the fuel system..at least 3/8" but preferably 1/2" line coming from the tank to an inline fuel filter. 1/2" from the fuel filter into the pump. 1/2" From the pump into another filter and then into a fuel log. Fuel log obviously has an arms going to each edelbrock carb (dual quad 1405). At the end of the log a Bypass regulator (preset at 7PSI). Inlet hooked to log, outlet plugged and a 3/8" line running as a return back to the tank.

Here's my questions....

Where the heck do I find a fuel log that has the arms coming out to match the hook up spacing on the bowls for a dual quad? Seems all of them are for dual feed single 4 BBL holley's or Demon's. Right now my D/Q setup has the edelbrock dual line/log, but there is no rear port for any type of regulator. I do not want to run the regulator before the log and have a deadhead system. Do I go with more of a Fuel block system? If so, where and how does a guy mount something like that? I don't want to end up with a pile of spaghetti draping all over the engine bay and would like to keep the plumping as narrowed down and efficient as possible.

As far as my return line to the tank....My 3/8" sending unit doesn't have a return port, but there is (2) 5/16" vent ports on the tank itself. Can I use one of them for the return and will it be adequate for the 3/8" return line?

Another question...What is with all the hype with AN fittings? I'm quite use to them from the military, but never thought they were that great. Why pay $5-10 bucks per fitting, when I can buy standard NPT for a quarter of the price? Is it just the easibility of using the AN with flex hosing instead of hard plumbing?

Sorry about all the questions, this 512 is outside the normal box I play in. Just trying to gather as much info as possible from you fella's that have played with these scenario's in the past and what's worked and what didn't and where to go from here.

Thanks guys!

I spent a half an hour on the horn with George at Clay Smith Cams yesterday...Heck of a guy with quite a racing pedigree. Really enjoyed the stories about his aluminum '64 mopar back in the day, pretty much a priceless car now days. Anywho, I came to the decision to run their high volume mechanical fuel pump on the 512 (14-19 PSI @140GPH), being it's way more than adequate for my motor and I really don't want to play with the electric's.

So...Here's what George recommended for the fuel system..at least 3/8" but preferably 1/2" line coming from the tank to an inline fuel filter. 1/2" from the fuel filter into the pump. 1/2" From the pump into another filter and then into a fuel log. Fuel log obviously has an arms going to each edelbrock carb (dual quad 1405). At the end of the log a Bypass regulator (preset at 7PSI). Inlet hooked to log, outlet plugged and a 3/8" line running as a return back to the tank.

Here's my questions....

Where the heck do I find a fuel log that has the arms coming out to match the hook up spacing on the bowls for a dual quad? Seems all of them are for dual feed single 4 BBL holley's or Demon's. Right now my D/Q setup has the edelbrock dual line/log, but there is no rear port for any type of regulator. I do not want to run the regulator before the log and have a deadhead system. Do I go with more of a Fuel block system? If so, where and how does a guy mount something like that? I don't want to end up with a pile of spaghetti draping all over the engine bay and would like to keep the plumping as narrowed down and efficient as possible.

As far as my return line to the tank....My 3/8" sending unit doesn't have a return port, but there is (2) 5/16" vent ports on the tank itself. Can I use one of them for the return and will it be adequate for the 3/8" return line?

Another question...What is with all the hype with AN fittings? I'm quite use to them from the military, but never thought they were that great. Why pay $5-10 bucks per fitting, when I can buy standard NPT for a quarter of the price? Is it just the easibility of using the AN with flex hosing instead of hard plumbing?

Sorry about all the questions, this 512 is outside the normal box I play in. Just trying to gather as much info as possible from you fella's that have played with these scenario's in the past and what's worked and what didn't and where to go from here.

Thanks guys!