451Mopar

Well-Known Member

I degree my cams, but my complaint is the quality of the cheap "kits" that make it difficult to get consistent and repeatable measurements.

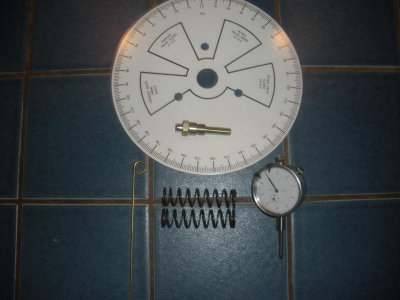

I am usually building about two engines a year, so I bought some of the items that make the job easier, like the crank turning socket that also holds the degree wheel, and the cam checking tool that replaces the lifter and holds the dial indicator. I got those parts from Powerhouse products, but that's $110 for just the two items, you still need a degree wheel and dial indicator. The smaller the degree wheel, the harder it is to read because the degree marks are closer together, but they can often be used when the engine is in the car. The large diameter degree wheels are easier to read and what I use when the engine is on the engine stand. I use the Comp/Powerhouse 16" pro degree wheel ($200) because the 1/4" thick aluminum has little run out. The thin steel wheels tend to get bent/distorted and wobble in/out where the pointer has to be spaced further away.

The Altronics DIGICAM digital degree system looks nice ($300), but I have not used one yet. If it has a data output?, and you used a digital indicator with data output, it would be easy to capture the entire cam lobe profile (and installed position) on a computer.

I am usually building about two engines a year, so I bought some of the items that make the job easier, like the crank turning socket that also holds the degree wheel, and the cam checking tool that replaces the lifter and holds the dial indicator. I got those parts from Powerhouse products, but that's $110 for just the two items, you still need a degree wheel and dial indicator. The smaller the degree wheel, the harder it is to read because the degree marks are closer together, but they can often be used when the engine is in the car. The large diameter degree wheels are easier to read and what I use when the engine is on the engine stand. I use the Comp/Powerhouse 16" pro degree wheel ($200) because the 1/4" thick aluminum has little run out. The thin steel wheels tend to get bent/distorted and wobble in/out where the pointer has to be spaced further away.

The Altronics DIGICAM digital degree system looks nice ($300), but I have not used one yet. If it has a data output?, and you used a digital indicator with data output, it would be easy to capture the entire cam lobe profile (and installed position) on a computer.