racedodge

Well-Known Member

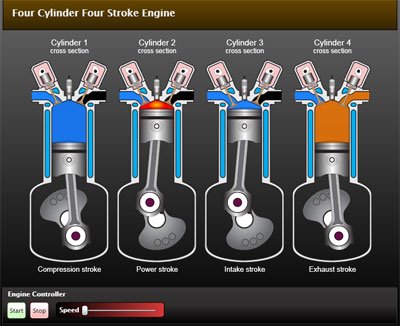

If your not sure about top dead center on compression stroke take off your valve cover. On the compression stroke both valves will be closed on #1. On the exhaust stroke both valves will be open on #1. The piston will be at tdc when the VALVES ARE FULLY SEATED ( THE ROCKER ARMS MAY HAVE A LITTLE WIGGLE TO THEM AT THIS TIME BECAUSE THERE UNLOADED)..

I agree with this except that on the exhaust stroke, only the exhaust valve is open.