Bigal75

Well-Known Member

- Local time

- 4:31 PM

- Joined

- Aug 18, 2011

- Messages

- 934

- Reaction score

- 230

- Location

- Ottawa Ontario Canada

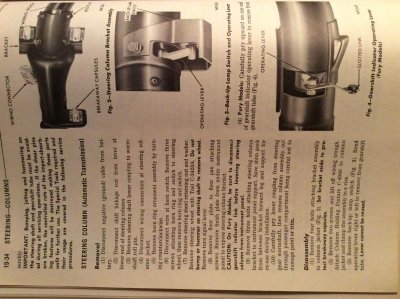

Car is a '67 Coronet R/T, 727 , I converted to manual steering with the adapter. My issue is I seem to have play in the main steering shaft that's connected to the coupler (factory one) - this causes a rattle and knock

in the column and it drives me insane - not to mention there's something definately wrong and I would hate for something to fail in the steering system.

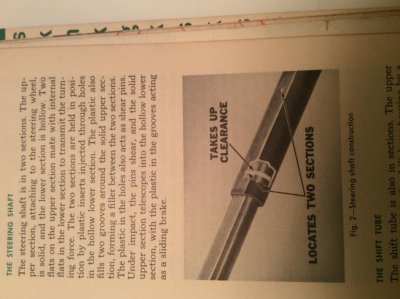

I did notice that the shaft that goes into the the column (intermediate shaft?) wiggles in the coupler and I can make it rattle - is there supposed to be some loose in there?

Also the shaft has play going into the column - is there supposed to be a bushing or something preventing this? This all started after I swapped out to manual steering - the box

seems nice and tight so I don't think the steering gear has issues.

Anyone come accross this type of issue?

in the column and it drives me insane - not to mention there's something definately wrong and I would hate for something to fail in the steering system.

I did notice that the shaft that goes into the the column (intermediate shaft?) wiggles in the coupler and I can make it rattle - is there supposed to be some loose in there?

Also the shaft has play going into the column - is there supposed to be a bushing or something preventing this? This all started after I swapped out to manual steering - the box

seems nice and tight so I don't think the steering gear has issues.

Anyone come accross this type of issue?