-

Are 440 and 383 fuel pump push rods the same?

yes they are the same.- 70Hemi

- Post #2

- Forum: Engine, Trans & Driveline

-

-

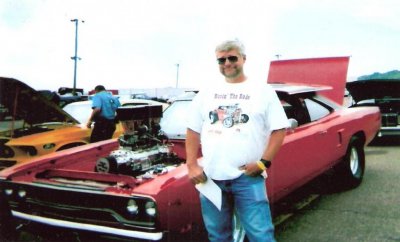

1970 RR pictures.

here is a couple from when I used to race at bandimere before moving to Alaska- 70Hemi

- Post #16

- Forum: 1968 -1970 Mopars

-

Dyno day for the hemi

awesome. would be interested what you all have in that motor. I have never had mine on a dyno.- 70Hemi

- Post #28

- Forum: Racers Hangout

-

Overcharging! Help!

long answer but will help you track down problem. use your meter to check all these out and than when you find the bad reading trace the probelm from there. 1. alternator- big threaded terminal 12v battery voltage key off, small spade terminal labeled (bat) 12v with key on, small spade...- 70Hemi

- Post #9

- Forum: Electrical & Ignition

-

Huston, we have a problem...!!!!

possible idea if you swapped heads on a running motor and are trying to roll it by hand I have seen were the lifters are pumped to take up clearance up for the old heads and do not release enough for the new setup. try figuring out the ones that are hitting and pull the lifter on that one and...- 70Hemi

- Post #32

- Forum: Engine, Trans & Driveline

-

-

want to do away with stock starter relay......

attached a pic of schematic i drew up for you. hope it helps. if you use a ford syle relay make sure you get the 4 wire not the 3 (the 3 wire ones ground through the mount) if you need a neutral saftey. will hook up the same battery + and wire to starter go on the 2 big side lugs and wire...- 70Hemi

- Post #7

- Forum: Racers Hangout

-

want to do away with stock starter relay......

oh ya one more thing .... if you mount your remote coming throught your firewall right behind the carb you and reach it from both sides and only need one switch- 70Hemi

- Post #3

- Forum: Racers Hangout

-

want to do away with stock starter relay......

i relocated all my wires on my hemi. wasnt too hard. you can just wire your remote switches right to the stock relay if you want to save some time but if you wanna clean up the engine compartment wiring than simply take all the power wires off the threaded lug of the stock relay and solder and...- 70Hemi

- Post #2

- Forum: Racers Hangout

-

Need help with 4sp trans

same trany, just watch input shaft spline 18 or 23, front bearing diameter, and tail shat, but small block big block isnt an issue- 70Hemi

- Post #3

- Forum: Engine, Trans & Driveline

-

Unusual Symptoms???

im still banking on a lean condition. i had a intake gasket leak between intake runner and lifter valley. i have seen heads and or blocks surfaced so much that the intake doesnt set low enough for the passages to line up right. everything you talk about just sounds like a vacuum leak somewere...- 70Hemi

- Post #19

- Forum: Racers Hangout

-

-

Unusual Symptoms???

my 2 cents worth ... if it revs up when you are hitting the acelerator pump by hand you a definatly lean. have you checked float levels in both float bowls? you said used carb.. was it working on another motor recently or was it laying around the shop? possible someone took it apart and used...- 70Hemi

- Post #6

- Forum: Racers Hangout

-

clutch disc separated

I had a problem like that on mine once. was using the 10.95" disc with 10.50 bolt pattern preasure plate (used to be called scalloped) and my outer edge of the clutch disc fiber was rubbing lightly on the preasure plate bolts. you could move it by hand and everything was adjusted and working...- 70Hemi

- Post #9

- Forum: Engine, Trans & Driveline

-

If you could find a car that you once owned..

I bought my 70 RR in 1980 when I was 15 and still have it. probably the only smart thing I ever did :)- 70Hemi

- Post #28

- Forum: General Discussion

-

What torsion bars to use?

I put the hemi in my '70 383 rr back in 1990 and just used the stock 383 torsion bars. drove it about 20,000 miles before i tubbed it and it drove just fine. glad to hear you upgraded to front disc brakes. the extra weight of that hemi sure made the front drum brakes seem worthless. good luck- 70Hemi

- Post #4

- Forum: Brakes, Steering & Suspension

-