firstgencharger

Well-Known Member

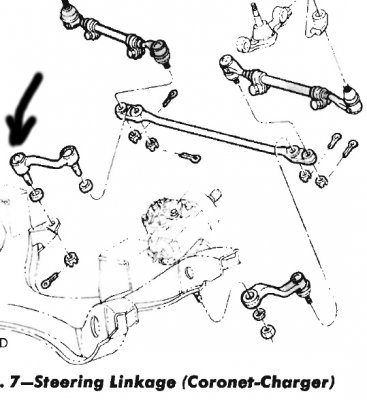

I'm rebuilding the front suspension on my 67 Charger. This is where I am stumped at the moment. I have the PST rebuild kit with new idler and pitman arms. The correct end of the idler arm is in the bracket, but I can't seem to get it to tighten.

It is in as (idler arm, felt washer, k-member bracket, steel washer then nut). When I try to tighten the nut, the stud just keeps spinning in the bracket end. I can't get any torque value, and the stud is very loose in the bracket. I've placed the old arm back in and can get it to torque down.

I measured the OD of the idler arm stud at about 1.54 and the center link hole where the stud enters at the same dimension.

What might I be doing wrong?

It is in as (idler arm, felt washer, k-member bracket, steel washer then nut). When I try to tighten the nut, the stud just keeps spinning in the bracket end. I can't get any torque value, and the stud is very loose in the bracket. I've placed the old arm back in and can get it to torque down.

I measured the OD of the idler arm stud at about 1.54 and the center link hole where the stud enters at the same dimension.

What might I be doing wrong?