- Local time

- 4:39 PM

- Joined

- Jul 31, 2011

- Messages

- 9,044

- Reaction score

- 4,138

- Location

- Western Colorado High Desert

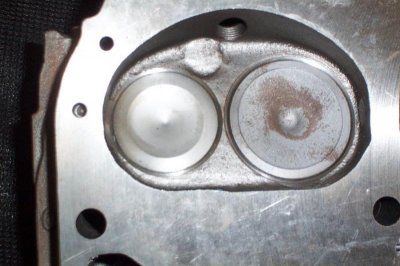

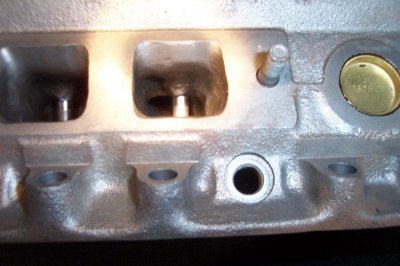

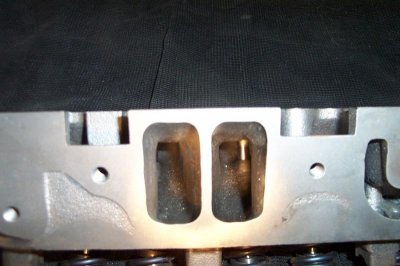

I just picked these up in Vegas. Would like to use them on a 440 with a .540-.580 roller cam. I'm a little concerned about the valve stem boss. Is a little rough.

Thanks:tongue7:

Thanks:tongue7: