- Local time

- 8:01 PM

- Joined

- Apr 13, 2012

- Messages

- 39,901

- Reaction score

- 147,609

- Location

- Granite Bay CA

First up, thanks to all who have followed along and offered advice to me with the problems that I ahve been dealing with.

To REcap:

I'm having some detonation issues running my Charger 440/493 on California 91 octane fuel. The engine has NO detonation when running 110 octane leaded fuel. It is a 440 block .030 over, 4.15 stroke, 10.7 calculated compression with 84 cc Edelbrock aluminum heads, Performer RPM intake 850 Demon, TTI 2" headers. MP electronic ignition with a chrome ECU.

On the advice of several members, I did a cranking compression test. I recorded some abnormally high numbers and posted them here. Some members were surprised at the numbers, thinking that they seemed wrong.

I decided to make the switch to new adjustable roller rocker arms in the 1.6 ratio. I installed them on the left side first. Just for the heck of it, I decided to recheck the compression numbers. When I went to grab the hose and guage, I noticed this:

- - - Updated - - -

The guage on the left STARTS at 30 PSI !! I never noticed it until now. What a rookie mistake!

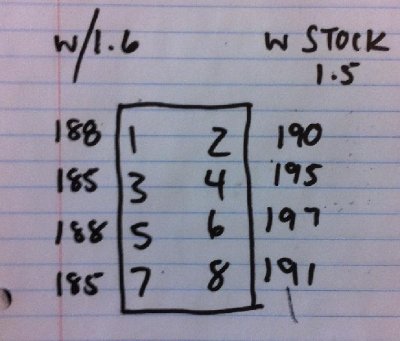

I rechecked the compression numbers with the guage that starts at zero.

- - - Updated - - -

Dwayne Porter was one guy that suggested that I try using another guage to see if I had made a mistake. Now that I am recording numbers closer to what is considered "streetable", I will finish the rocker install on the right side. I have new spark plugs and wires to install and a new 6 quart oil pan. For now I'm hoping to get it to run without spark knock. Later I will consider steps to increase the power.

Thanks again everyone.

To REcap:

I'm having some detonation issues running my Charger 440/493 on California 91 octane fuel. The engine has NO detonation when running 110 octane leaded fuel. It is a 440 block .030 over, 4.15 stroke, 10.7 calculated compression with 84 cc Edelbrock aluminum heads, Performer RPM intake 850 Demon, TTI 2" headers. MP electronic ignition with a chrome ECU.

On the advice of several members, I did a cranking compression test. I recorded some abnormally high numbers and posted them here. Some members were surprised at the numbers, thinking that they seemed wrong.

I decided to make the switch to new adjustable roller rocker arms in the 1.6 ratio. I installed them on the left side first. Just for the heck of it, I decided to recheck the compression numbers. When I went to grab the hose and guage, I noticed this:

- - - Updated - - -

The guage on the left STARTS at 30 PSI !! I never noticed it until now. What a rookie mistake!

I rechecked the compression numbers with the guage that starts at zero.

- - - Updated - - -

Dwayne Porter was one guy that suggested that I try using another guage to see if I had made a mistake. Now that I am recording numbers closer to what is considered "streetable", I will finish the rocker install on the right side. I have new spark plugs and wires to install and a new 6 quart oil pan. For now I'm hoping to get it to run without spark knock. Later I will consider steps to increase the power.

Thanks again everyone.