Sprag

Well-Known Member

Wednesday's progress - finally in the shop!

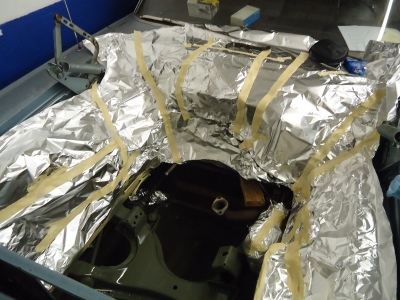

Well, got her in the shop the other day, what a relief to finally get time to work on this terlit. The plan was to hang the brakes so it could go on the trailer to storage but soon discovered I got the wrong shoes for the rear so the crusty tank came out instead. Onward and upward......

Got a sinking feeling that maybe, just maybe the wire ties and worm clamps are not original from ma Mopar....

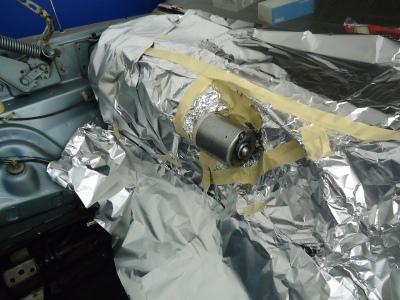

Maybe the same for the goo-fest attempt at sealing the leaky tank - not original? :icon_puke_l:The black goo had the tank strap fused to the tank but the air saw made quick work of that (sorry for crappy pics)

Some numbers on top of the tank, hidden under the insulation mat thingy. Kidding aside, I have no idea if the tank is original but I think it might be. Not sure what to make of the numbers anyway.......

I've got a new Canuck tank/strap/sender from Spectre and everything looks nice with their stuff (sorry no picks of new tank). Old sender has seen it's days:

Ran out of time so I decided to stop here so I can replace the brake lines and hose on the rear axle next. It looks to be much easier to do with the tank out of the way for that. Got her off the lift and we managed to make room to keep it in the shop - woo-hoo!

The freshly painted wheels sure look nice eh?

- - - Updated - - -

Today's progress revolved around leaving the car where it sits, no lift time for now. So I went after the front end since I have most everything to fix what's bad there (ball joints, brakes, shocks etc). Note the only body rust through on this one is at the lower fenders. This will get the cave-n-pave later, patch panels would be a waste of money for this.

I've only done a handful of upper ball joints on Mopars and this was the first time I got one out with just a breaker bar size ratchet. What a relief that was. The plan is to upgrade the (wasted) tie rods using later larger CBody stuff, parts ordered and mind you, they are cheaper than the locally found BBody stuff. Stay tuned.

Well, got her in the shop the other day, what a relief to finally get time to work on this terlit. The plan was to hang the brakes so it could go on the trailer to storage but soon discovered I got the wrong shoes for the rear so the crusty tank came out instead. Onward and upward......

Got a sinking feeling that maybe, just maybe the wire ties and worm clamps are not original from ma Mopar....

Maybe the same for the goo-fest attempt at sealing the leaky tank - not original? :icon_puke_l:The black goo had the tank strap fused to the tank but the air saw made quick work of that (sorry for crappy pics)

Some numbers on top of the tank, hidden under the insulation mat thingy. Kidding aside, I have no idea if the tank is original but I think it might be. Not sure what to make of the numbers anyway.......

I've got a new Canuck tank/strap/sender from Spectre and everything looks nice with their stuff (sorry no picks of new tank). Old sender has seen it's days:

Ran out of time so I decided to stop here so I can replace the brake lines and hose on the rear axle next. It looks to be much easier to do with the tank out of the way for that. Got her off the lift and we managed to make room to keep it in the shop - woo-hoo!

The freshly painted wheels sure look nice eh?

- - - Updated - - -

Today's progress revolved around leaving the car where it sits, no lift time for now. So I went after the front end since I have most everything to fix what's bad there (ball joints, brakes, shocks etc). Note the only body rust through on this one is at the lower fenders. This will get the cave-n-pave later, patch panels would be a waste of money for this.

I've only done a handful of upper ball joints on Mopars and this was the first time I got one out with just a breaker bar size ratchet. What a relief that was. The plan is to upgrade the (wasted) tie rods using later larger CBody stuff, parts ordered and mind you, they are cheaper than the locally found BBody stuff. Stay tuned.