You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

68 charger

- Thread starter cdr

- Start date

cdr

Well-Known Member

Nice work! Funny, I was just test fitting my connectors and boxes, turn my computer on and see your same ones installed. What type welder are you using?

250 mig,,,,install the connectors 1st then the boxes

mopar4don

Well-Known Member

Did you install these with all the weight of the car down on its suspension?

I have read somewhere that this is recommended. Don't really know myself, was just wondering if this was true and if you did yours this way?

I have read somewhere that this is recommended. Don't really know myself, was just wondering if this was true and if you did yours this way?

cdr

Well-Known Member

yes they are very wideHey, looking good. How much of a gap do you have between your rocker and door? I can fit my pinky finger in between mine. Seems a bit much.

Mr.SpeedFreak

Well-Known Member

- Local time

- 11:52 PM

- Joined

- Jan 29, 2013

- Messages

- 1,645

- Reaction score

- 1,056

- Location

- Southern Oregon

Did you install these with all the weight of the car down on its suspension?

I have read somewhere that this is recommended. Don't really know myself, was just wondering if this was true and if you did yours this way?

Yeah Charles most manufacturers tell you to have the full weight of the car (drivetrain, interior, etc) before you do the connector install cause the subframe positions will want to shift relative to each other as you add weight, think they're worried about that putting too much stress on the car. Hopefully yours will be fine cause everything is looking awesome! Might be something to check out though

cdr

Well-Known Member

yes stands under the axle & lower control armsDid you install these with all the weight of the car down on its suspension?

I have read somewhere that this is recommended. Don't really know myself, was just wondering if this was true and if you did yours this way?

- - - Updated - - -

thanx speed freak ! it'll be ok they are concerned about body lines & gaps,the way i did it will be no problem.Yeah Charles most manufacturers tell you to have the full weight of the car (drivetrain, interior, etc) before you do the connector install cause the subframe positions will want to shift relative to each other as you add weight, think they're worried about that putting too much stress on the car. Hopefully yours will be fine cause everything is looking awesome! Might be something to check out though

Mr.SpeedFreak

Well-Known Member

- Local time

- 11:52 PM

- Joined

- Jan 29, 2013

- Messages

- 1,645

- Reaction score

- 1,056

- Location

- Southern Oregon

yes stands under the axle & lower control arms

- - - Updated - - -

thanx speed freak ! it'll be ok they are concerned about body lines & gaps,the way i did it will be no problem.

No problem! Just would've hated to see you have to cut that one back out. To do it safely did you just have all the gaps where you wanted them and the car level on stands to where it'd "lock in" those gaps or how did it work?

cdr

Well-Known Member

before i took the car apart i leveled & i lined up all the panels,also measured the complete car using the x pattern ,the gaps did not change after taking it apart,the car strings out very good,so thats the way it got welded up.No problem! Just would've hated to see you have to cut that one back out. To do it safely did you just have all the gaps where you wanted them and the car level on stands to where it'd "lock in" those gaps or how did it work?

mopar4don

Well-Known Member

before i took the car apart i leveled & i lined up all the panels,also measured the complete car using the x pattern ,the gaps did not change after taking it apart,the car strings out very good,so thats the way it got welded up.

"also measured the complete car using the x pattern" ,"the car strings out very good"

Can you explain?

cdr

Well-Known Member

an example would be take the engine compartment,take a reading from drivers side upper fender mounting stud to pass hood bumper in the front,do the same on the other side ie pass stud to driver front,it should come out the same ,or very close,that checks for it being bent ie diamond .you can pick reference spots all over the car .[the car strings out good] means it measures out good

daytona kid

Well-Known Member

Mr.SpeedFreak

Well-Known Member

- Local time

- 11:52 PM

- Joined

- Jan 29, 2013

- Messages

- 1,645

- Reaction score

- 1,056

- Location

- Southern Oregon

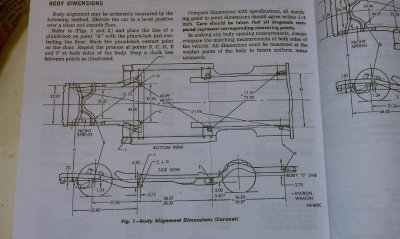

I am using this, along with my own measurements. It's from a factory service manual that is sold on the net.

Damn I need to get me one uh those lol. Everyone keeps helping me out with scanned pictures from the service manual, might finally break down and eBay it

cdr

Well-Known Member

wife out of town so i was able to get the drivers side connector & torque boxes in today

daytona kid

Well-Known Member

Just curious why US Car Tool would have a pic on there site of connectors being welded on like this? I'm planning on tak welding mine till loaded.Yeah Charles most manufacturers tell you to have the full weight of the car (drivetrain, interior, etc) before you do the connector install cause the subframe positions will want to shift relative to each other as you add weight, think they're worried about that putting too much stress on the car. Hopefully yours will be fine cause everything is looking awesome! Might be something to check out though

Attachments

- Local time

- 11:52 PM

- Joined

- Jan 16, 2011

- Messages

- 74,467

- Reaction score

- 114,784

- Location

- NorCal Sierras

Just curious why US Car Tool would have a pic on there site of connectors being welded on like this? I'm planning on tak welding mine till loaded.

I'm probably over **** about this stuff...LOL... BUT Maybe the inside of the car was X-braced up, before they took it completely apart, to make sure it was all weight loaded/stressed properly, nothing would move too much that way & so everything would fit after welding, jump around when welding also so it doesn't pull too much in any one direction from all the heat...... my thoughts anyway

cdr

Well-Known Member

modifying floor board to clear overdrive & grind on trans for clearance,still workin on the cross member.

- - - Updated - - -

- - - Updated - - -

Donny

Well-Known Member

- Local time

- 1:52 AM

- Joined

- Aug 28, 2009

- Messages

- 3,206

- Reaction score

- 543

- Location

- North East San Antonio TX

Nice thread, nice work, and, hope you recover CDR! Question, the flag on our information, your's is Israeli, yet you say you're part of the CSA in Katy Texas. Ironic, I just toured the CSA White House in Richmond, a most excellent tour and fascinating history!

cdr

Well-Known Member

Nice thread, nice work, and, hope you recover CDR! Question, the flag on our information, your's is Israeli, yet you say you're part of the CSA in Katy Texas. Ironic, I just toured the CSA White House in Richmond, a most excellent tour and fascinating history!

thank you donny,i would love to go check out the CSA white house,i fly the Israel flag in support of the JEWISH people,i believe in what the big book says

cdr

Well-Known Member

welded my cross member together today,now gotta drill holes & on to the next project.

Similar threads

- Replies

- 0

- Views

- 3K

- Replies

- 13

- Views

- 1K

- Replies

- 18

- Views

- 1K

- Replies

- 56

- Views

- 9K