- Local time

- 5:28 AM

- Joined

- Apr 13, 2012

- Messages

- 40,093

- Reaction score

- 148,763

- Location

- Granite Bay CA

Looking great. I love the look of a fresh engine.

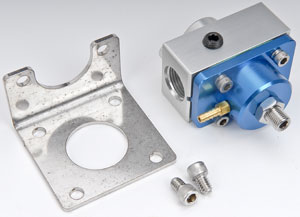

I also attached a picture of the position of the rocker on the valve, which looks pretty good to me. We're running about 320 pounds of total spring load with this hydraulic roller setup. You can see the Crower lifter in the last pic too...

Tell me more about your springs...rate, installed height, please...

Didn't you say you were using the stock RPM springs? Catalog says max lift of .600" and I thought you said cam lift was .588"...and that some 'things' had to be done to them? Shimming is the only thing I can think that could be done, which would screw w/ installed height.... Coil bind/compressed coil clearance an issue?

Can you not get the tip centered any more? Looks a bit off...what's the sweep pattern look like?

Valve Lift: The installed cam is .582 "advertised" max lift. I believe the "advertised lift" figure listed for the cam refers to the actual valve lift given a standard rocker arm ratio - 1.5 in the case of a Mopar head. So 0.582" IS the total valve lift, and the total "cam lift" is actually 0.582 / 1.5, or 0.388". Interestingly, this figure (0.388") is the figure listed for Duration at .050" Lobe Lift. I have always assumed that Duration at .050" Lobe Lift is the number of degrees during which the valve is open by AT LEAST .050". Is it a coincidence that my total cam lift is the same as my Duration at .050" Lobe Lift? Someone wiser than I will know the answer. (VALVE-TRAIN WIZARDS HELP HERE)

Advertised Camshaft Specifications

Intake: Duration 312*, .582 lift

Exhaust: Duration 312*, .582 lift

Duration at .050" Lobe Lift:

Intake: 236*

Exhaust: 236*

110* LSA

Intake: .388

Exhaust: .388

And on that note...

I'm back with the Road Racing Engine thread. My stock 440 block is now at the machine shop with a Mancini Racing internally balanced 493 stroker kit sitting next to it - a complete short block rotating assembly ready to go together. Now we're talking about cams and types of cams. The shop is a fan of Crower cams (they say they like the billet they are made from) and recommends going with a hydraulic roller setup. I'm not opposed to either for any reason that I know of. I don't mind the ease of maintenance of a hydraulic. I don't mind the limited RPM (6,500 or so) because I don't expect to be above there anyway with my setup (3.55 rear end, 727 auto trans / 2,500 RPM stall converter, 27-28" tire) . Crower doesn't have a stock Chrysler 440 hydraulic roller cam in their catalog, but the machine shop suggests going with a custom grind.

I spoke to them about the oil clearance issue and they have no problem with that because they build boat motors all the time. The problem is, the shop guy keeps telling me: You're not gonna find a cam that is good for sustained "high RPM" road racing and still comfortable on the street. To refresh your memory, what we are trying to build here is an engine that will hum along comfortably at 4,000 to 5,00 RPM, which is what it takes to go 100+ in a 3.55 Roadrunner for an hour or more.

Now I didn't tell him I need maximum horsepower at 4,000 to 5,000 RPM. I just need SUSTAINED operating at 4,000 to 5,000 RPM with enough horsepower to maintain the high speed over varied highway terrain. I know that I can keep my Roadrunner at 100+ MPH on just the stock 335HP that my 383 makes (less, since it DEFINITELY doesn't make 335HP in its current condition). So that means that as long as the motor makes 300 to 400HP between 4,000 and 5,000RPM. I'm good to go.

It can't be THAT hard to come up with a cam profile that will do that and still be streetable right? (I'm planning on standard Edelbrock performer RPM 84cc heads, my existing Schumacher tri-y headers, good ignition and some big carb.). It'll probably be closer to 450+HP in that range I'd guess. Obviously the car will spen more time on the street trolling around than on the "track" at 100+MPH.

Here's a proposed grind based on a Lunati cam from Mancini:

Item# LUN60304LK

$218.95

Product Description

Hydraulic. Hot Street cam, likes 2800 converter, Hi-Rise type dual plane intake with 850cfm carb, headers, 10:1 compression and 3.73 gears. Likes up to 200HP nitrous.

Advertised Duration (Int/Exh): 276/284

Duration @ .050 (Int/Exh): 234/242

Gross Valve Lift (Int/Exh): .513/.533

LSA/ICL: 110/106

Valve Lash (Int/Exh): Hyd/Hyd

RPM Range: 2200-6400

Anyone care to check my calculations and my logic? Be gentle!

Thanks

Greg

Still curious about the springs...

Hey guys how do I know what size air cleaner I'm gonna need for this new engine? Is there a way to calculate the max CFM for a 493 and convert that into a size? As in 2" high by 14" diameter, or 3" high by 16" diameter?

I was looking at (thousands of) air cleaners and it occurred to me that many of them may be unable to provide the amount of air the engine needs. It's gotta be a a CFM vs. surface area problem, but I don't know how to solve it...

Thanks

WOW on the Dakota Digital pkg.

Like others, I am a total newb on electrical so am watching this for all the details you can add. When you are splicing into the harness does this include routing around the 'bulkhead connector"? From Dakota Digital ads it appears that the harness feeds the modules, then 'outputs' via Cat5 to the gauge cluster?