Ask Professor Prop,

Hi Prop, I have a question about your block. Did you say it was a late 70's truck block? If it is, they are thin wall by design right? How did you bore it out enough to accept the 512 cid? I understand it's a stroker kit and it's the stroke as well as the bore that's been changed but from what I have read a thin wall block can only be bored .020 over. Did you sleeve the block? I have a 77 440 block that I would like to use to get to 512 like you did but I'm afraid of the thin wall cracking.

Sincerely,

Cracking up in Michigan

IMHFO I think that's just an Internet "wives tale, fallacy", there's very little differences in the casting, some material casting formula changes, core shift is more of an issue, than a supposedly a later years "thin cylinder wall casting" or nickel more or lack of nickel content in the B-RB blocks, in the B Low Deck blocks the 400 series is a better block, than the 350-361-383 blocks, the 400's main webbing is strongest, if you building a High HP/TQ B-RB Mopar wedge engine, you should use for block strength,

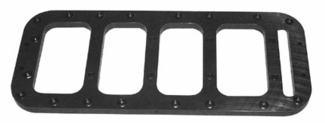

a block girdle & main cap studs, "at a minimum", then some better cap materials

{& even cross bolts, but it ain't cheap}, if you want to be more safe, but below 500Hp or so it's not really necessary, but it's relatively cheap insurance, if you already spend $2000 on a stroker kit & $2000 for a properly done set of heads, $1000 on machine work, $1500 on fuel pump carb & manifold, larger A/N lines regulator & larger sending unit, $700 on headers etc., then another few hundred, for block strength, isn't too much to spend, to protect your investment & peace of mind...